Speaking with professional experts who are experts in the subject might offer a bit of help.

The concept of production leveling might appear abstract at first and very recondite to follow.

It encompasses taking time, working slowly & consistently, and taking buffer inventory when due. When this is properly done and products are provided in their relevant timeframe, manufacturing firms are able to meet their real demand better. Heijunka is the key to reducing lead time in organizations. This, in effect, reduces costs and helps you level the lead time and the stockpiles up. This challenge, however, can be countered by reducing the time between equipment takeovers, allowing for buffering. Let’s now assume that you’re producing different types of electronic products, this might be a herculean task to manage. This reduces capital costs and other production processes. Then, for the remainder of the week, the production team produces 100 pieces of the goods constantly daily. As a result, there is always a stock of 100 pieces available for Monday mornings. Let’s say you are the producer of mobile phones and you receive an order to supply 500 pieces of your phone to a particular client every week, 200 pieces on Monday, 100 pieces on Tuesday, 50 pieces on Wednesday, 100 pieces on Thursday, and 50 pieces on Friday.Īll you have to do is to follow the demand leveling principle by stocking 100 pieces close to delivering every Monday.

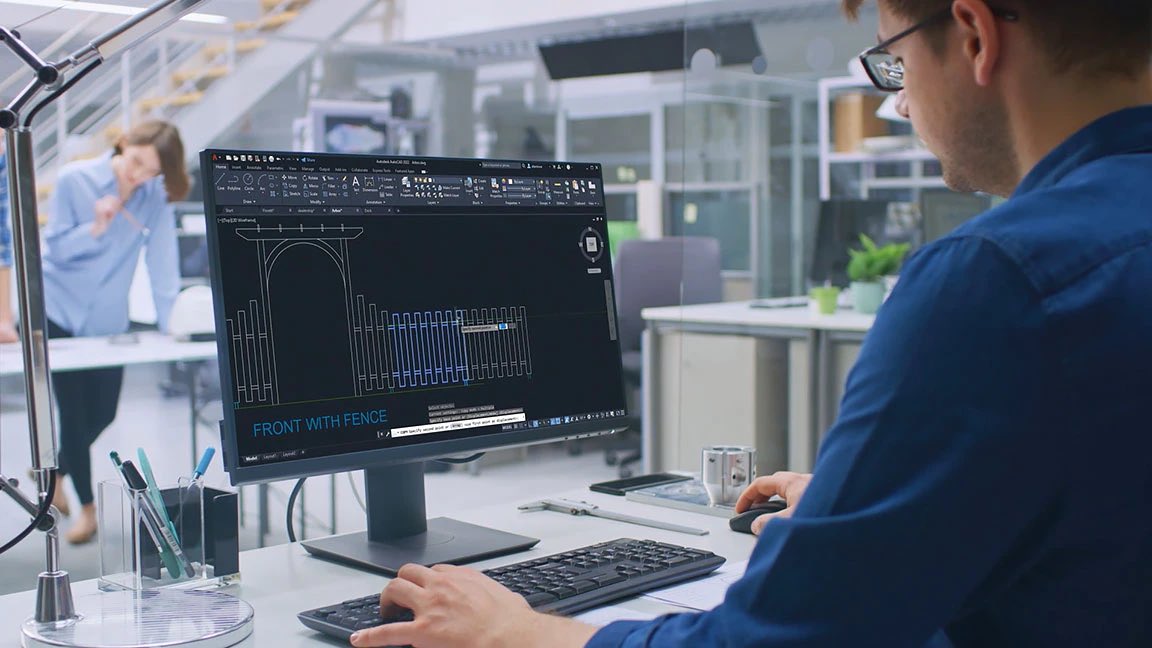

Approaches to production leveling Volume leveling This process, according to experts, is best to implement at the final production line to minimize fluctuations in production. The aim of the process is to produce goods at a constant rate so that in trying to meet up with high demand, the extra processing is done at a uniform and predictable rate. The name, production leveling, is from the Japanese word “Heijunka” which means “leveling” and is a strategy to eliminate waste. Production smoothing or production leveling is the process by which firms satisfy the demands of their customers whilst reducing production wastes in the form of capital costs, manpower, and production lead time, to the barest minimum. Should we fold our hands and allow these factors to continue to cause loss to your business? No! That’s why you’re reading this article on how to level production. There are disasters, inherent flaws, and a very high tendency to estimate wrongly. Learn what production leveling is, how to level production, and how Autodesk Prodsmart can help.Īll things being equal, all things are not equal.

0 kommentar(er)

0 kommentar(er)